Algrow

Individual work

Fluidotech

A.Y. 2018-2019

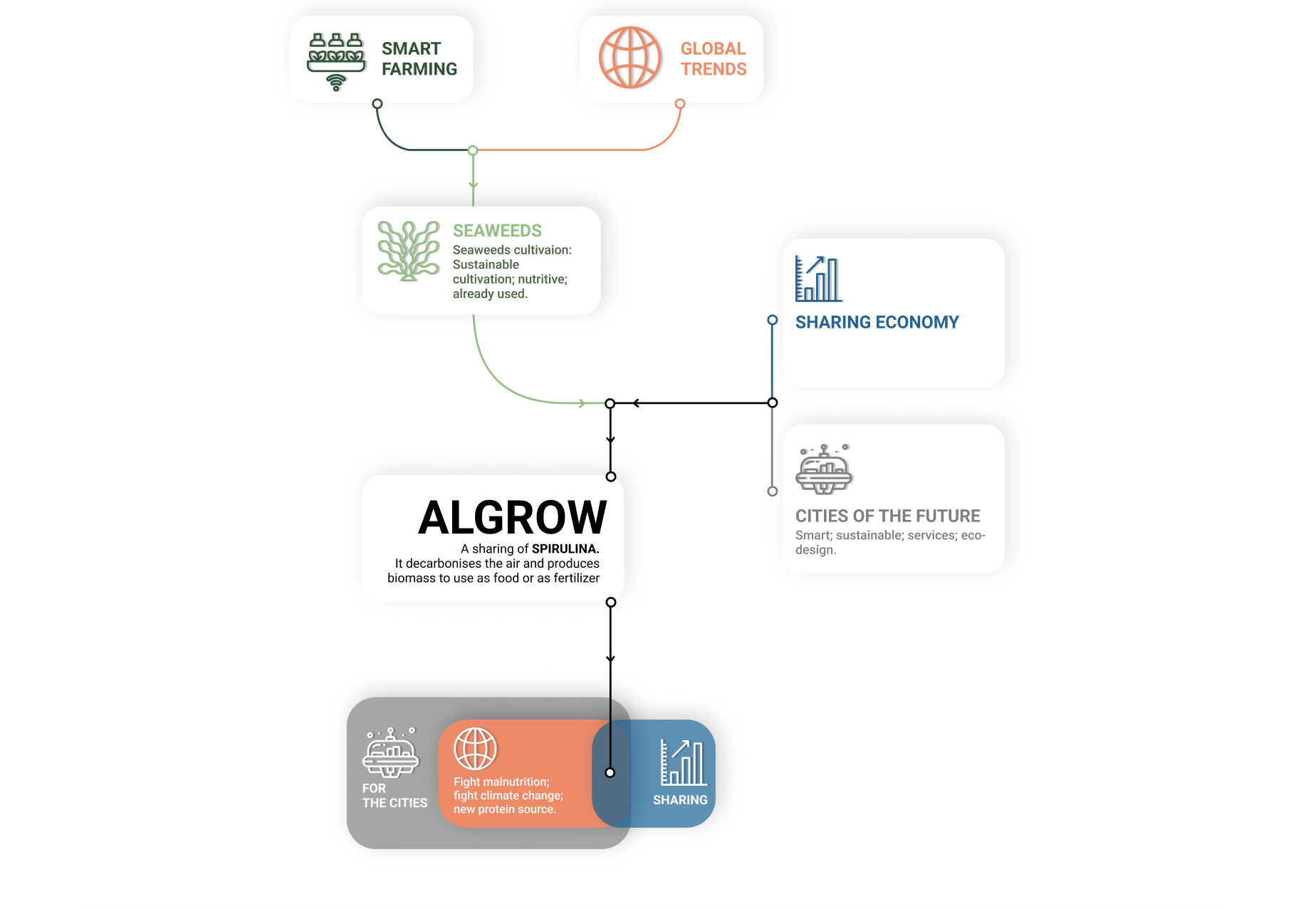

Algrow is a spirulina dispenser for cities or municipalities. It has two main functions: it decarbonizes the air and produces microalgae biomass, that can be used as food or fertilizer. The project was created to bring different values. In a small way, it could contribute to fight climate change, by reducing CO2; fight malnutrition, as microalgae are highly nutritious; it offers an alternative to the protein sources already being consumed.

Scenario

It is estimated that by 2030 the population will increase from the current 7. 3 billion to 8. 5 billion and this will necessarily lead to a physiological increase in the demand for food. We should neither underestimate the change in the nutritional value of food, which is being depleted in terms of macro and micronutrients due to the excessive use of fertilizers and pesticides, but above all due to the impoverishment of the soil. At the same time, the number of people looking for food produced with eco-friendly processes is growing. Algae can grow fast and they can do it even in wastewater. This leads us to think that they could be a more sustainable alternative to other foods already in the world’s diets..

Why Spirulina?

The blue algae known as Spirulina is a complete food with a remarkable nutritional profile. With 65% protein content, Spirulina is the most complete source of plant-based protein in nature, with maximum digestibility (85-97%) and the lowest amount of fat and cholesterol (5%). As if that wasn't enough, this algae boasts other records: it is the richest existing natural source of beta-carotene, 10 times more concentrated than carrots. 10 grams of Spirulina provide 55% of the daily iron requirement, as well as calcium, magnesium, and zinc. Among all edible microalgae, Spirulina is the most famous and is currently already used by some foreign markets.

Photobioreactor

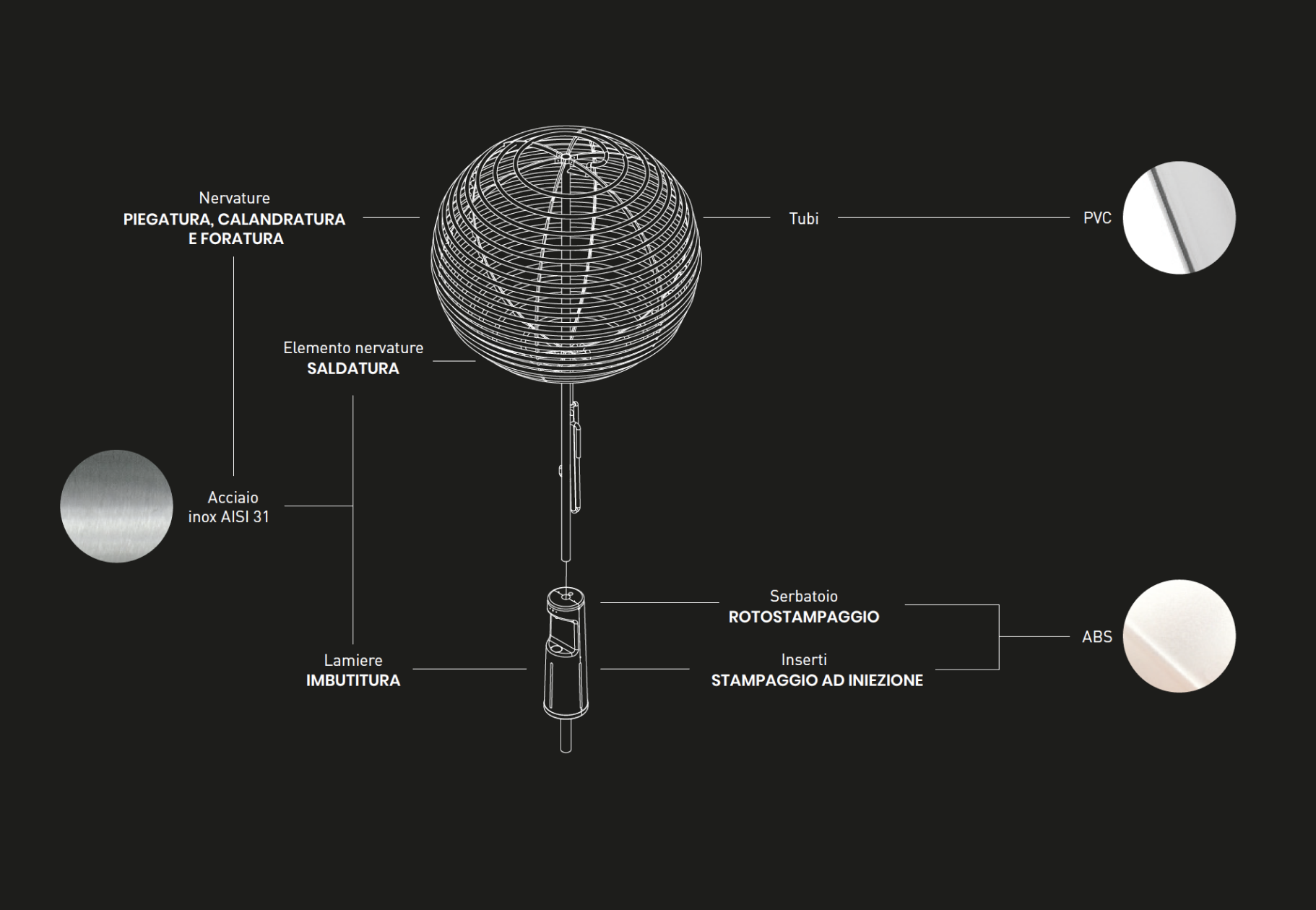

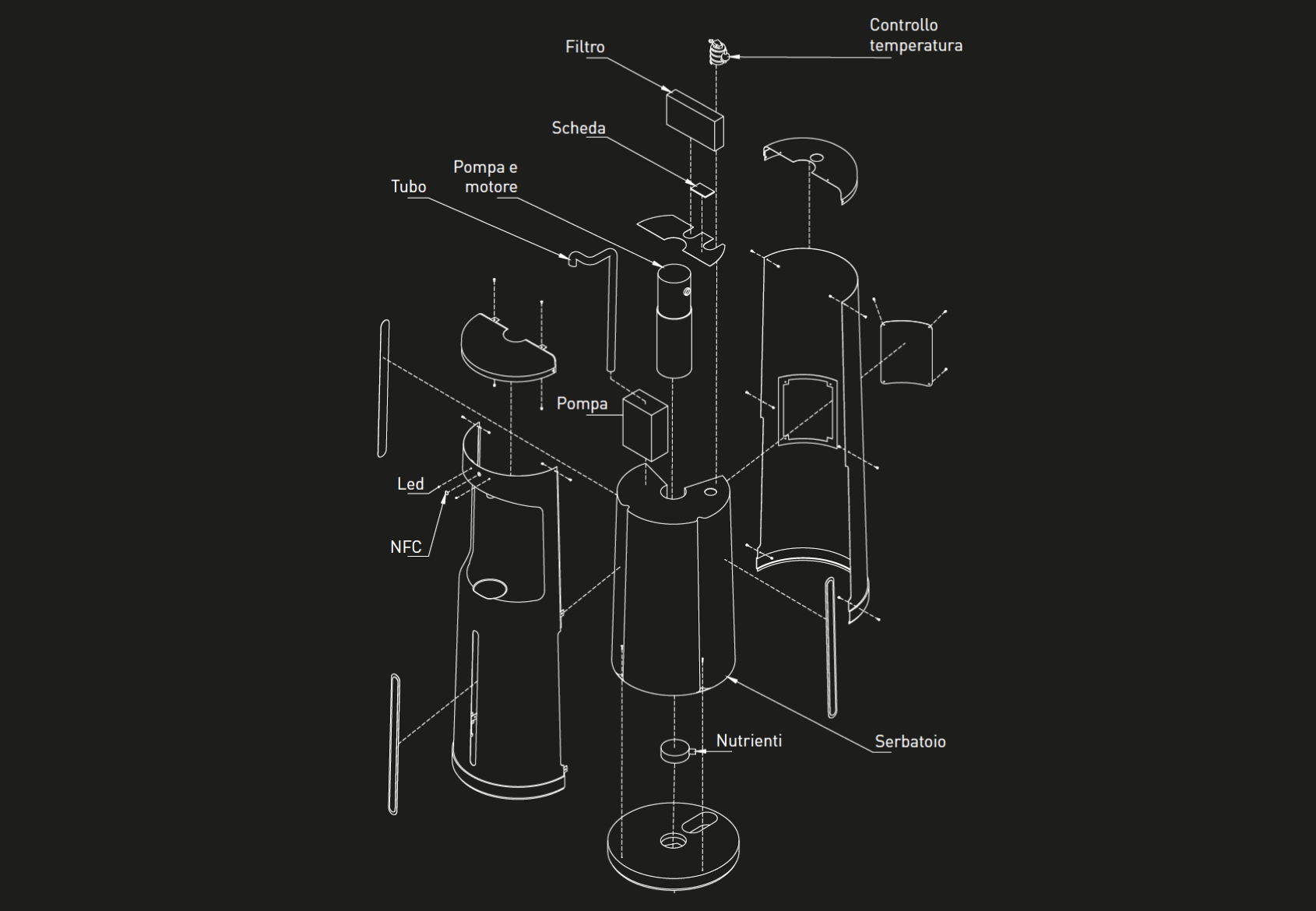

Algrow’s method of cultivation is the photobioreactor: a closed equipment that provides a controlled environment and allows for high algae productivity. The algae are contained in a system of tubes and since it is a closed system, all algae growth requirements are introduced into the system and controlled. PBRs facilitate a better control of the growing environment.

The structure

Algrow consists of: a system of tubes, a dispenser, and a structure. Inside the dispenser shell, there is a tank supported and bolted to a concrete base. The water recirculation system composed of the fluid-o-tech vane pump and the motor rests on top of the base. For temperature control, there is a temperature sensor, a mini compressor, and a mini chiller on the top of the tank. Thanks to a specific nutrient dispenser connected to a pH, CO2, and O2 sensor, a perfect environment is maintained inside the tubes to promote algal growth. A filter, programmed to turn on and off during the day, separates the water from the spirulina, with the former returning to the system and the latter being conveyed into the tank.

Pains

Due to COVID-19 this project was developed entirely online. As it was the first time for us, it was difficult to be stimulated and to find inspiration for generating ideas, which was the most difficult phase to deal with.

Takeaways from the project

Working with ProntoPro and discovering the specific dynamics of their work has been very inspiring. Developing a platform for the first time, made me realize what needs to be considered while designing UI. I discovered and applied the MEDGI methodology for the first time.